Dal Prete

Just Water 3.1

Wastewater Clarifier

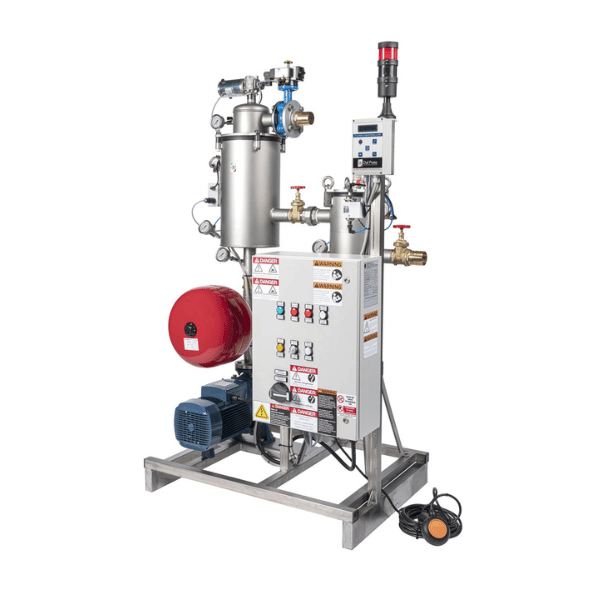

Just Water 3.1

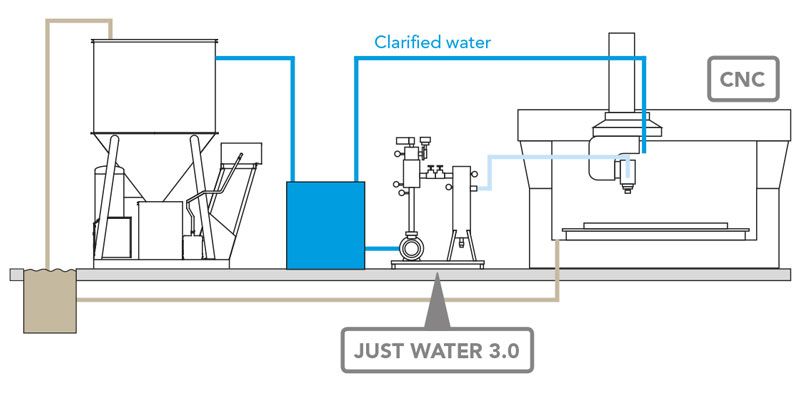

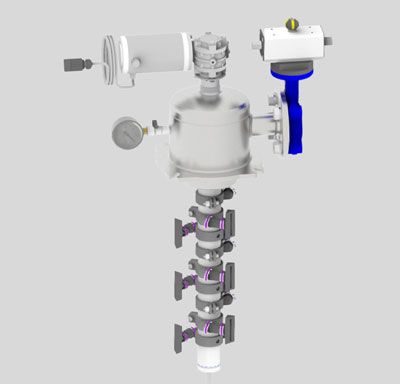

Just Water 3.1 is an advanced dual-stage water filtration unit designed for CNC machines. It filters clarified water down to 5 µm, reduces water consumption, and ensures uninterrupted flow—even during automatic self-cleaning.

Who Is It For?

Workshops using one or more CNC machines that want to reduce fresh water use

Facilities experiencing wastewater discharge who want to recycle and refine existing clarified water

Production environments seeking consistency, reliability, and reduced maintenance

Features and Advantages

Filters clarified water to reduce waste and lower water consumption.

Self-cleaning rotary system minimises maintenance requirements.

Fully automatic operation saves time and reduces risk of human error.

Ensures a continuous, uninterrupted water flow—even during the cleaning cycle.

Filtration

Up to 5 μm

Scope

Up to 40 l/min

Up to 10 US gal/min

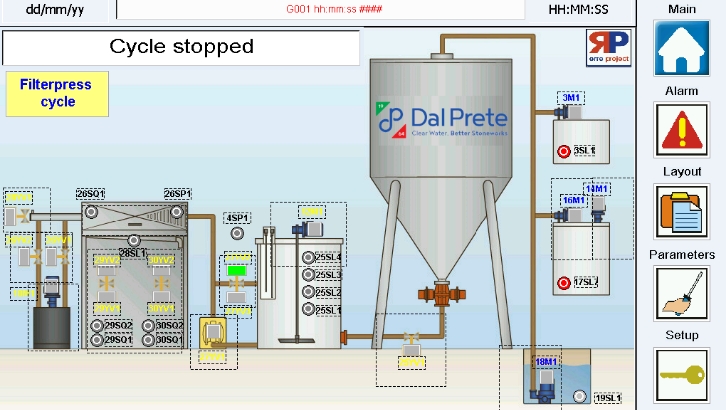

DPURE Software

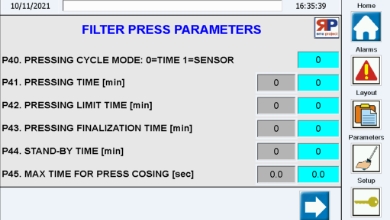

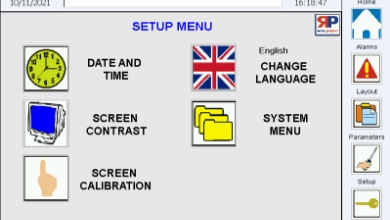

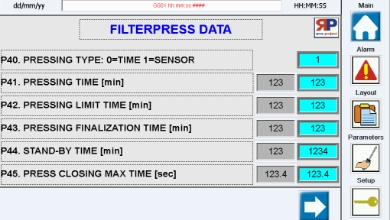

DPURE is Dal Prete’s proprietary software, developed and refined over time to meet the practical needs of its customers. It offers tailored solutions that streamline the scheduling and management of clarification and dehydration operations, making plant processes faster and more efficient.

With a focus on automation, DPURE ensures consistent and error-free performance across all stages of the treatment cycle. Its highly customisable functionality allows it to be adapted to each production site’s unique workflow and goals, enhancing both reliability and operational control.

The DPURE software installed on the Mini Compact L 2.1 is perfectly suited for stone workshops that handle large volumes of water and sludge. Designed for structured production environments, it simplifies the management of the entire water treatment cycle, offering a streamlined and efficient solution tailored to high-demand operations. Beyond controlling the clarification and dehydration processes, DPURE also manages the filter press water collection system, using automatic drip trays for easier and cleaner sludge disposal.

MAIN FEATURES

10” touch screen with display and control of all plant components

LAN connection for telematic assistance

Complete and automated control of clarification and dehydration cycles

Planning of dehydration cycles in line with production needs

Complete management of alarms with alerts on the integrated touch screen and optionally via SMS

Possibility of software customisation